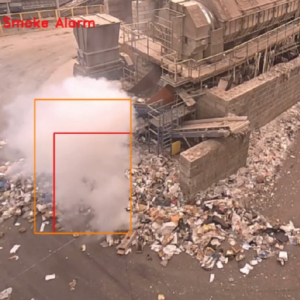

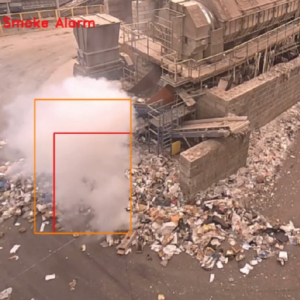

Video Smoke and Video Fire Detection

Ensuring safety in high-risk and operations-critical zones is paramount, and a trustworthy fire detection system plays a crucial role in

High risk, high speed, high value processes? Spark detection is the answer!

Even the tiniest spark can cause a devastating fire.

In many high-risk processes, a spark can be created with alarming ease. From shredding at a waste recycling facility through to high energy processes at a timber sawmill or biomass production plant there is a multitude of ways for a tiny spark or hot particle to be created. Immediate spark detection is a must, otherwise they can go on to cause a serious fire or dust explosion.

Some typical applications for spark detection are:

Spark Detectors are designed to detect all infra-red radiation (within a certain frequency range) and are highly effective in areas such as dust extract systems or conveyor belts where a potential fire source (although not necessarily a flame) could occur.

Flame detectors looks for specific frequencies of UV or IR radiation to detect a flaming fire.

Spark detectors however, look only for the infra-red radiation generated by fires, sparks and glowing embers to ensure that any fire risk (whether flaming or not) is efficiently detected – even in high levels of obscuration and dense or fast-moving materials flow.

Spark detectors are best used to protect against a specified risk (rather than flame detectors which are suitable for more generic use) and enable you to detect a small spark/fire before it develops into a flaming fire.

Contact us today for more information and advice about Spark Detection

Don’t hesitate to reach out to us, or you can easily fill out the form below. We’re here to assist you.

Ensuring safety in high-risk and operations-critical zones is paramount, and a trustworthy fire detection system plays a crucial role in

High Sensitivity Smoke Detection (HSSD) systems are excellent for protecting high risk, high value environments where early detection is essential.

Linear Heat Detection Cable (LHDC) is a reliable and robust form of heat detection, suitable for the harshest environments and