Fire Sprinkler Systems

Fire Sprinkler systems are a very effective and reliable way to protect almost any building or asset from fire. They

Condensed aerosol fire suppression systems are a unique method of extinguishing a fire inside a room or enclosed area, and they offer many benefits. Condensed aerosol is a dry agent that leaves little residue is non-harmful, non-destructive, and does not require a completely ‘air-tight’ enclosure to be effective.

Aerosol fire suppression is ideal for machinery spaces such as CNC machines, generator rooms, robot cells, electrical switchgear, hazardous storage areas, and many other applications.

Aerosol fire suppression systems extinguish a fire like gaseous suppression agents by ‘flooding’ the volume of the protected area with billions of tiny airborne particles of extinguishing agent. This creates an atmosphere in which fire cannot exist, as the airborne particles prevent the ‘free radicals’ from a fire from burning.

Compared to many suppression systems, they are relatively cheap to install. They do have the disadvantage that there is a fine residue of dust left behind, which could cause damage to sensitive electronic equipment such as server rooms; however, this does need to be balanced with what damage there would be in the room if there were a fire anyway.

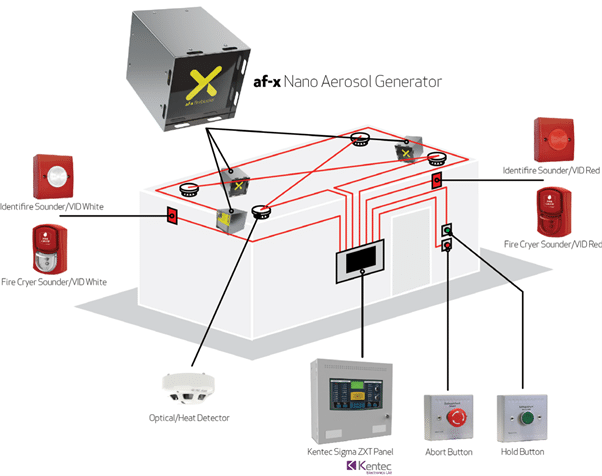

As with all suppression systems, there is a dual coincidence (also known as double knock) detection system. This means both detection methods must be activated before the actual suppression system is activated to prevent accidental agent release.

These systems release a cloud of condensed aerosol particles into the protected area. The aerosol interrupts the chemical reactions occurring in the flame, removing heat and inhibiting combustion.

This breaks the process known as the ‘feedback loop of fire‘. This process can be seen in this video of an aerosol generator undergoing fire testing.

Condensed aerosol systems are effective against Class A and B, which include ordinary combustibles, flammable liquids, and electrical fires <75kV.

Aerosol is also effective against Class C fires and has proven effective against lithium-ion battery fires. However, it is critical to consider whether you are exchanging the fire risk for an explosion risk in suppressing fires of this nature.

With fires of this nature, you may suppress the flames, but the flammable gases or vapours (such as electrolyte vapours in the case of batter fires) are uncombusted, uncontrolled – and have the potential then to be ignited suddenly, causing an explosion.

Generally, condensed aerosol systems are considered environmentally friendly. The aerosol particles are non-toxic, and many systems use agents that have minimal impact on the ozone layer. However, it’s essential to check the specific formulation of the aerosol agent.

The time it takes to suppress a fire with condensed aerosol systems can vary based on factors such as the fire’s size, the aerosol’s concentration, and the specific application. Generally, these systems act quickly, often suppressing fires within seconds to minutes.

As with any airborne extinguishing agent, the ‘hold time’ of the extinguishing agent is just as critical as its ability to knock out the flames. When the extinguishing agent is released, the fire is swiftly suppressed. However, the conditions which created the fire (fuel, heat and oxygen) are still present. If the extinguishing agent is removed from the environment and no longer inhibits the flames from occurring, the fire could re-occur.

That’s why aerosol needs an enclosed room/area to operate effectively, even if the room is not fully air-tight. This allows the agent to hold for at least 10 minutes.

If extraction systems are in the protected area, these should be shut off. If there are large ‘leakage’ areas in the protected area, a secondary discharge of condensed aerosol is sometimes required several minutes after the primary discharge to maintain the aerosol concentration in the protected area.

Some advantages include rapid and effective fire suppression, reduced damage to protected assets due to the lack of water or foam, compact design, and minimal maintenance requirements.

While condensed aerosol systems are versatile, they may have limitations in extremely large or open spaces. The concentration of aerosol particles needed to suppress a fire effectively may be challenging to achieve in such environments.

Aerosol is best suited to machinery/industrial environments and electrical switchgear applications as it leaves a fine dusty residue. The residue (comprised of potassium salts) is non-corrosive but should be cleaned promptly from sensitive equipment by vacuum cleaning, brushing, or blowing with compressed air, as it is hygroscopic (meaning it attracts moisture from the air).

Thus, the longer it sits, the harder it becomes to clean away.

As such, whilst aerosol is suitable for protecting sensitive equipment, including data centres and server rooms, it is rarely the first choice for these environments. Completely clean agents like inert gas are the optimal solution.

However, if these ‘clean’ agents are not a viable solution, then aerosol is an excellent alternative. ‘Clean agent’ gaseous fire suppression systems are more expensive to install and maintain.

Crucially, the requirement for ‘room integrity‘ on a gaseous suppression system can cause significant builders costs to meet the rigorous requirements of preventing the gaseous agent from escaping from the protected room – rendering gaseous fire suppression impractical.

Ultimately – a fire will be far more damaging to your sensitive equipment than the residue that a condensed aerosol fire suppression system may leave!

If not discharged during their lifetime, the aerosol generators should be replaced after 15 years, and the old generators should be returned to the manufacturer for recycling.

If discharged in a fire, the aerosol generators should be replaced with new units, as they are designed for a single discharge only.

The steel casing that houses the generator can be recycled once discharged.

Trained professionals should perform installation; regular maintenance is crucial to ensure the system’s reliability. Maintenance typically involves periodic checks of the system components and ensuring that the aerosol generators are functional.

While the aerosol used is generally non-toxic, safety measures should still be taken during the discharge, such as ensuring proper ventilation and following guidelines for evacuation.

Yes, reputable condensed aerosol fire suppression systems should comply with industry standards and regulations, such as those set by organizations like NFPA (National Fire Protection Association) and UL (Underwriters Laboratories).

These areas are rarely suitable for the use of other extinguishing agents, due to the nature of construction in the building, the size of the area, or the risks of water damage when using sprinklers or water mist to protect such valuable and sensitive assets. Aerosol will provide a non-destructive means of cost-effectively protecting these areas.

If you buy the wrong aerosols – possibly yes! Some of the early generations of aerosol generators were extremely crude, lacking basic safety features in their designs, and did literally emit flames during discharge.

This is because the chemical reaction that takes place during the discharge of an aerosol generator (transforming a solid block of compound into billions of tiny airborne particles) is a high-temperature exothermic reaction. All aerosol generators reach a high temperature during discharge – ask for the datasheets for the product you’re having installed, and the casing temperature and discharge temperature should all be recorded there.

However, with the new ‘second-generation’ aerosol generator products that we use, there is no concern about them venting flames.

Improvements in technology and the design of the aerosol generator eliminate that possibility. Part of the UL9450 testing that our aerosol generators undergo is that the aerosol is activated and discharged within an explosive atmosphere – and it goes without saying that during discharge, the aerosol is not allowed to ignite that explosive atmosphere!

So, in summary, there is no need to panic. So, as long as you buy quality, certified aerosol systems from reputable suppliers like Blazequel, you don’t need to worry about those outdated aerosol horror stories!

As always… it depends. There are many variables to consider here!

Firstly, let’s assume that you are looking to protect a room and do not require an ATEX-approved aerosol generator.

Secondly, let’s assume that your room is approximately 5m(long) x 4m(wide) x 3m (high).

Thirdly, let’s assume that we can use a cost-effective form of detection. We’ll use a system with a combination of smoke and heat detectors. One smoke detector and one heat detector will have to be activated to discharge the system (or alternatively, the system can be manually released).

For a system like this, you’ll have three main costs to consider:

In summary, a system like the one we described above could cost between £9,500 and £23,000 (+VAT) to design, supply, install, and commission. If you’d like to discuss your application, we’ll gladly provide you with an accurate quotation for your aerosol fire suppression requirements. Call us now!

Fire Sprinkler systems are a very effective and reliable way to protect almost any building or asset from fire. They

water cannons are fixed position fire extinguishing nozzles that can be used to directly target a fire at your facility.

brilliant solution for high-risk areas, where the sometimes-slow reaction speed of sprinkler systems will allow too long for the fire

If you have questions call us at +44 (0)1234 357357 or email us at sales@dev.blazequel.com or book a free consultation with us.